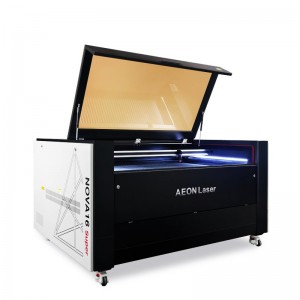

AEON NOVA14 Laser Engraver & Cutter

Advantages of the NOVA14

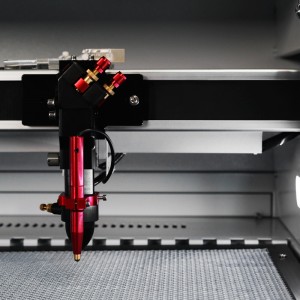

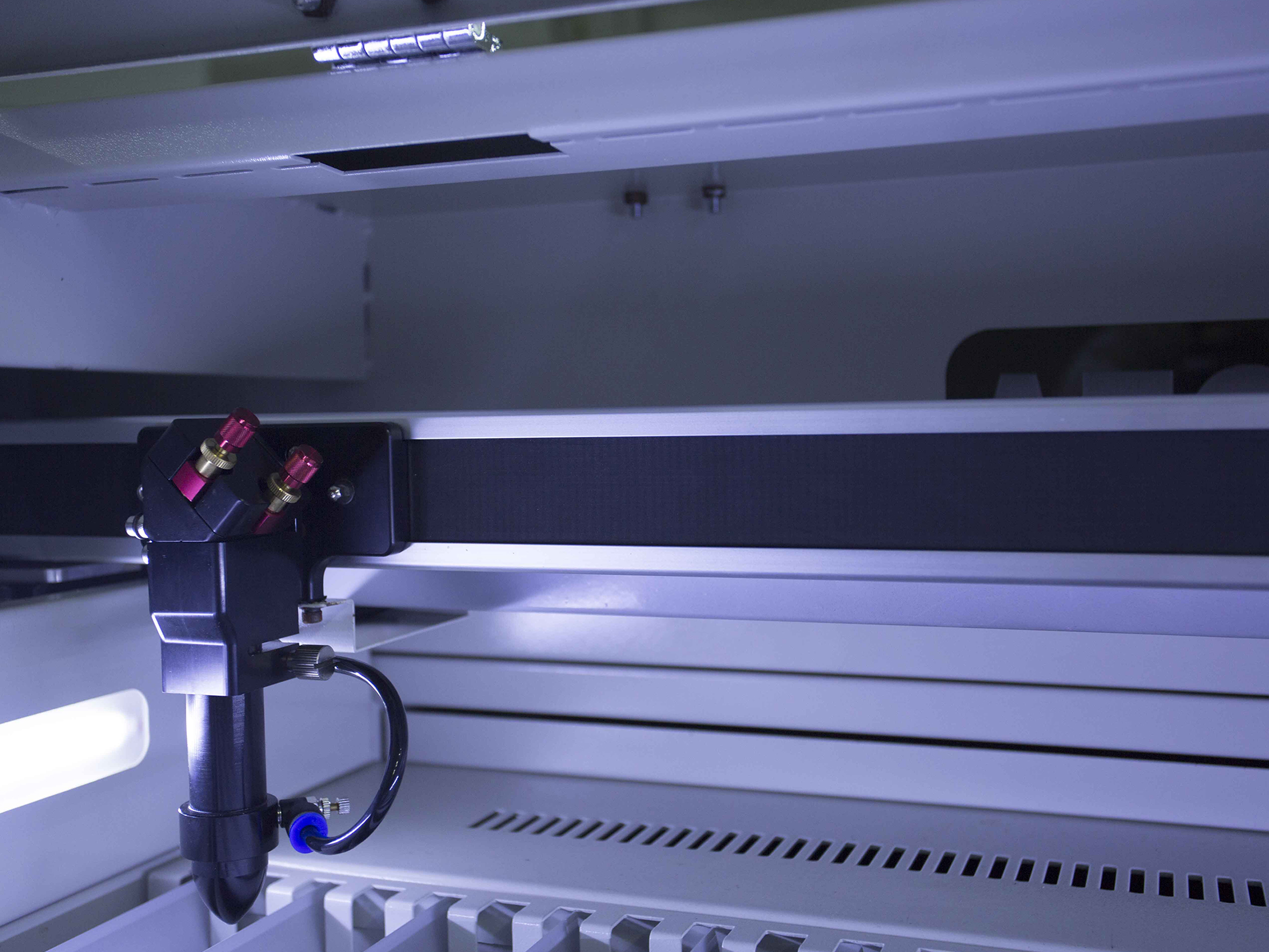

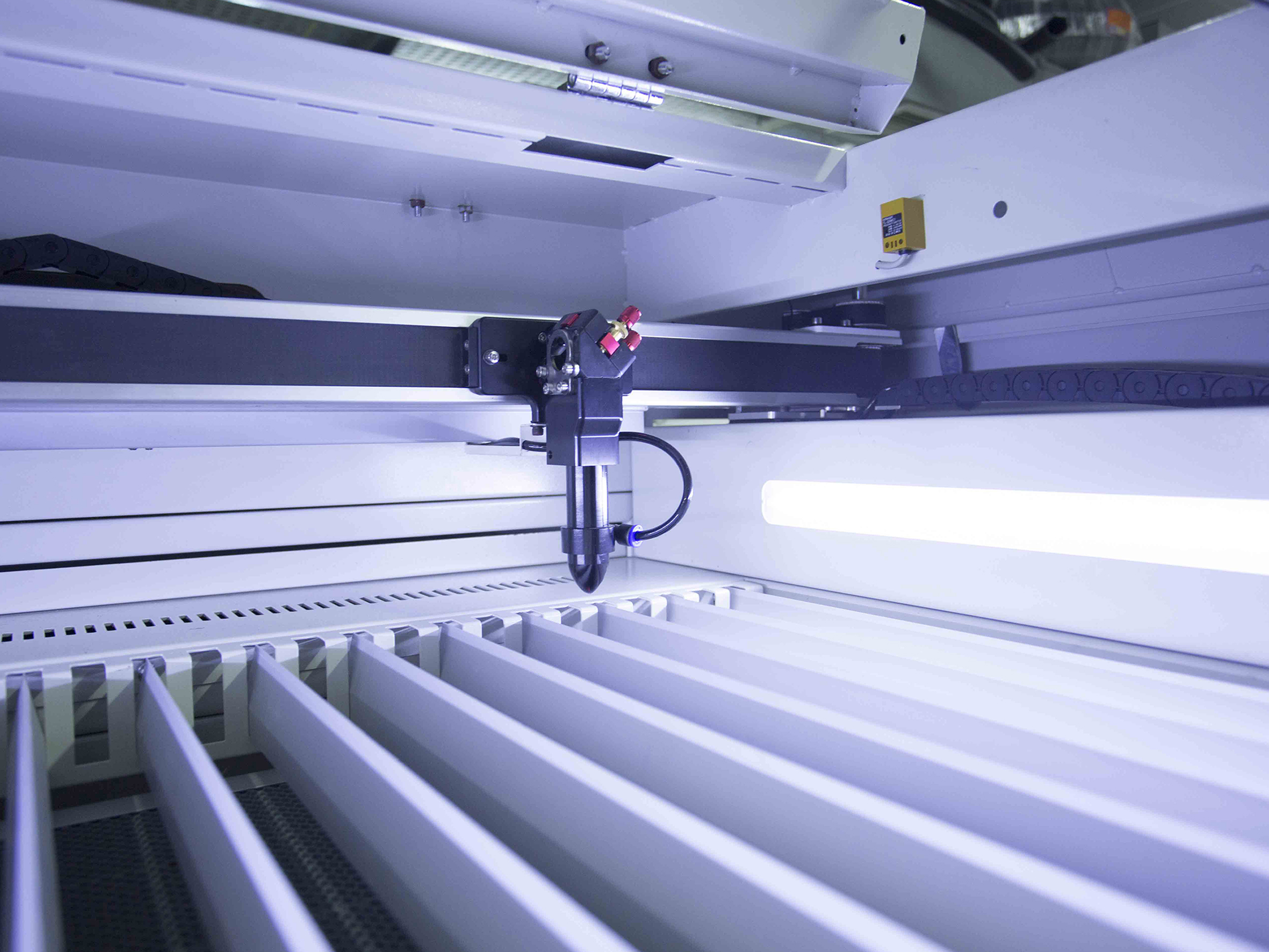

Clean Pack Design

One of the biggest enemies of laser engraving and cutting machines is dust. Smoke and dirty particles will slow down the laser machine and make the outcome bad. The Clean pack design of NOVA14 protects the linear guide rail from dust, reduces maintenance frequency effectively, gets a much better outcome.

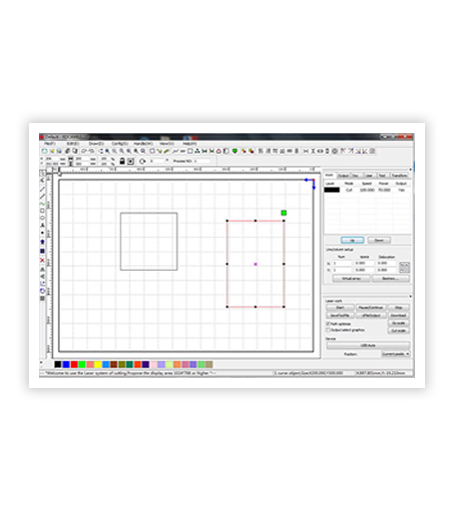

AEON ProSMART Software

The Aeon ProSmart software is user-friendly and it has perfect operation functions. You can set technic details and operate it very easy. It will support all file formats as using on market and can direct work inside of CorelDraw, Illustrator and AutoCAD. Even you can use a direct-print function like printers CTRL+P.

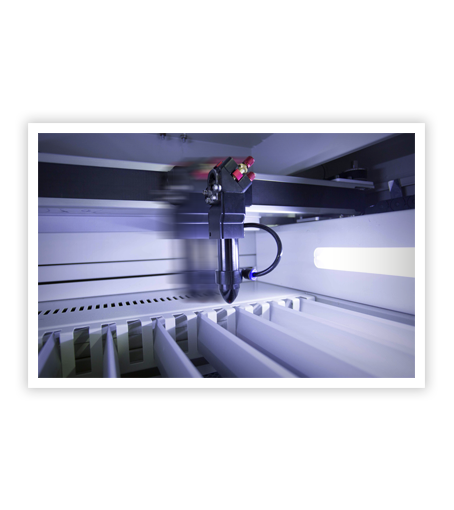

Faster Than Others

The new NOVA14 designed a maximum effective working style. With the high-speed digital step motors, Taiwan made linear guides, Japanese bearings, and maximum speed design it will up to 1200mm/second engraving speed, 300 mm/second cutting speed with 1.8G acceleration. The best choice in the market.

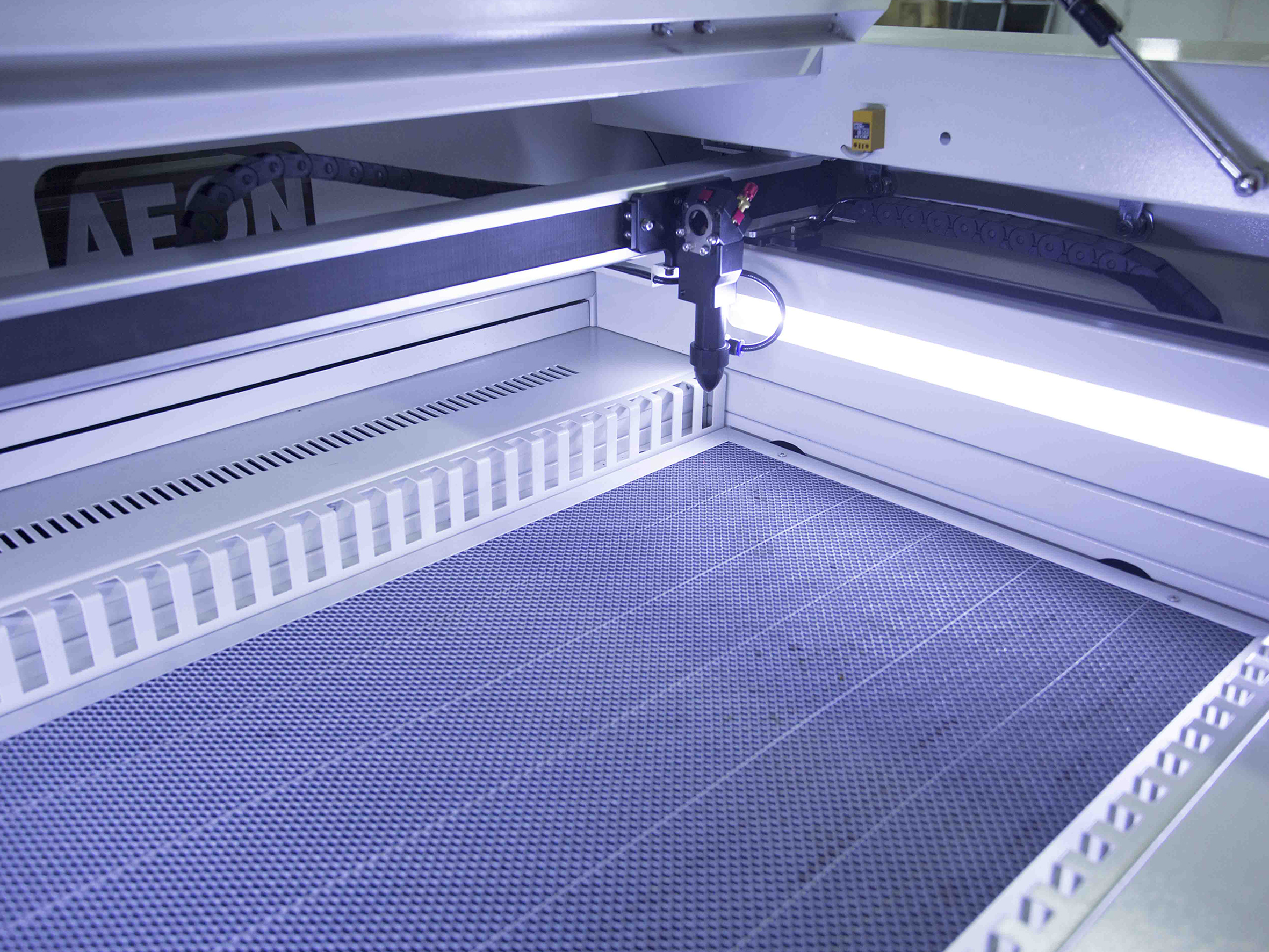

Strong, Seperatable and Modern Body

The new Nova14 was designed by AEON Laser. It was built on 10 years of experience, customer feedbacks. The body can separate 2 parts to move it from any door size 80cm. LED Lights from left and right side looking machine inside view very bright.

Multi Communication

The new NOVA14 was built on a high-speed multi-communication system. You can connect to your machine by Wi-Fi, USB cable, LAN network cable, and transfer your data by USB Flash disk. Machines have 256 MB memory, easy use color screen control panel. With off-line working mode when your electricity is down and the open machine will run on stop position.

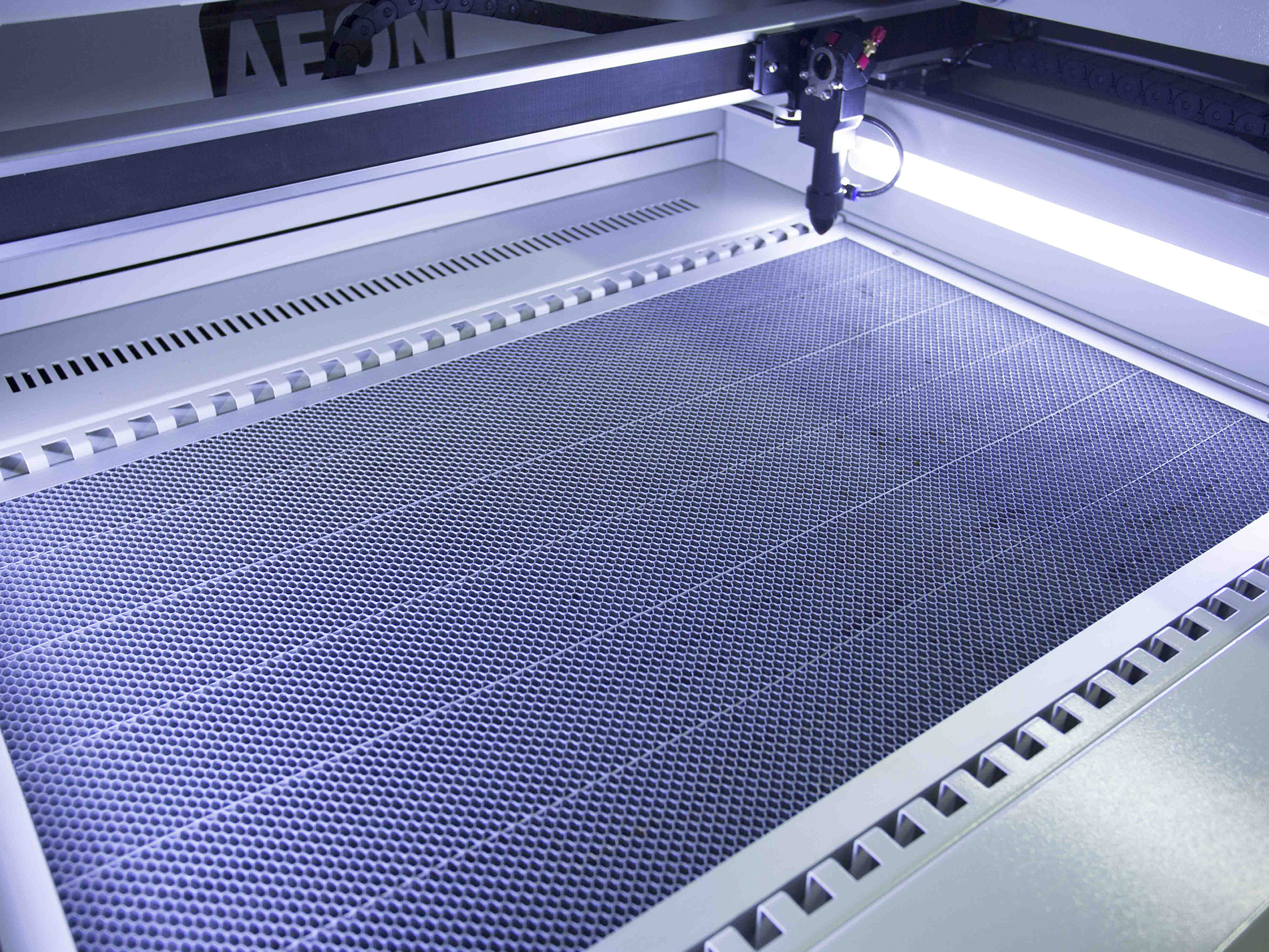

Multi Functional Table Design

Depends on your material you have to use different working tables. The new NOVA14 has a HoneyComb table, Blade table as standard configuration. It has to vacuum under the honeycomb table. With the pass-through design easy Access to use big size material.

*Nova models have a 20cm up/down lift platform with the vacuuming table.

Material Applications

| Laser Cutting | Laser Engraving |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

*Cannot cut hardwoods like mahogany

*CO2 lasers only mark bare metals when anodized or treated.

| Technical Specifications: | |

| Working Area: | 1400*900mm |

| Laser Tube: | 60W/80W/100W/150W(150W need tube extender) |

| Laser Tube type: | CO2-sealed glass tube |

| Z Axis Height: | 200mm |

| Input Voltage: | 220V AC 50Hz/110V AC 60Hz |

| Rated Power: | 1200W-1300W |

| Operating Modes: | Optimized raster, vector, and combined mode |

| Resolution: | 1000DPI |

| Max Engraving Speed: | 1200mm/sec |

| Acceleration Speed: | 1.8G |

| Laser Optical Control: | 0-100% set by software |

| Minimum Engraving Size: | Chinese Character 2.0mm*2.0mm, English Letter 1.0mm*1.0mm |

| Locating Precision: | <=0.1 |

| Cutting Thickness: | 0-10mm(depends on different materials ) |

| Working Temperature: | 0-45°C |

| Environmental Humidity: | 5-95% |

| Buffer Memory: | 128Mb |

| Compatible Software: | CorelDraw/Photoshop/AutoCAD/All kinds of Embroidery Software |

| Compatible Operation System: | Windows XP/2000/Vista, Win7/8//10, Mac OS, Linux |

| Computer Interface: | Ethernet/USB/WIFI |

| Worktable: | Honeycomb and aluminum bar table |

| Cooling system: | water cooling |

| Air Pump: | external 135W Air Pump |

| Exhaust Fan: | External 750W blower |

| Machine Dimension: | 1920mm*1495mm*1025mm |

| Machine Net Weight: | 450Kg |

| Machine Packing Weight: | 500Kg |