Factory Outlets Laser Engraving Machine Co2 - Nova14 Super – AEON

Factory Outlets Laser Engraving Machine Co2 - Nova14 Super – AEON Detail:

Overall Review

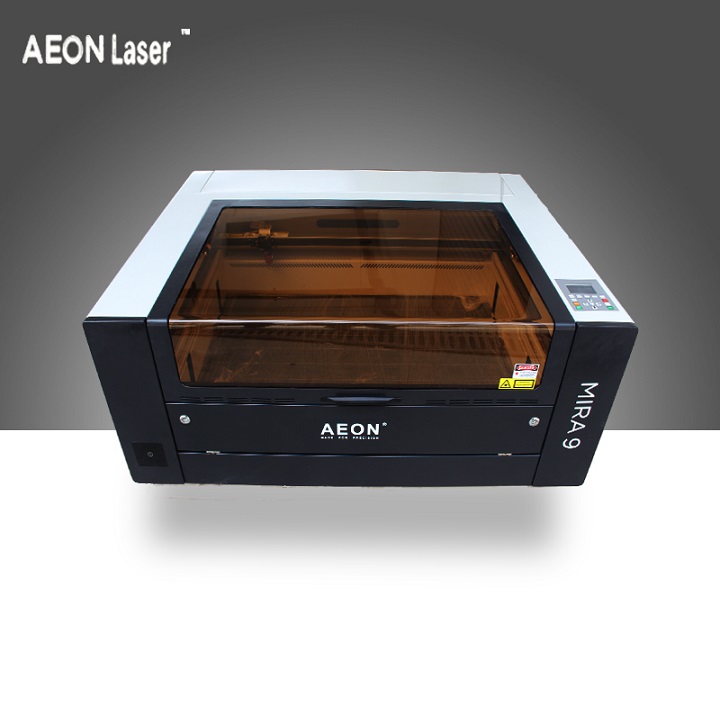

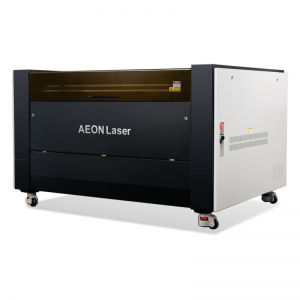

Super Nova14 is a professional co2 laser engraving and cutting machine. The working area is 900*1400mm. Super Nova10 offers the Metal RF & Glass DC in one machine. Nova14 Super’s engraving speed is as fast as MIRA series machines. Also can go 2000mm/sec, the acceleration speed is 5G, has the fastest speed in its class.

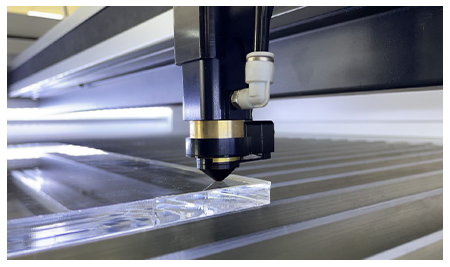

The structure of the Nova14 super is very strong, which makes it more steady. The machine equipped with honeycomb and blade worktable and with model 5200 chiller, makes it possible to install 100W or even 130W laser tube. The Z-axis now increased to 200mm, so it can fit in higher products. The air assists system got pressure gauge and regulator to give the users option to add a more powerful compressor to cut thicker materials. The front and back material pass-through door makes it possible to cut long materials.

Advantages of Nova14 Super

Super Strong Fully Enclosed Machine Body

The Super NOVA14 is built like a tank. The main structure adopted a thick steel tube, which ensured strength. The whole body was fully enclosed, with sealing on every door and window, more safety.

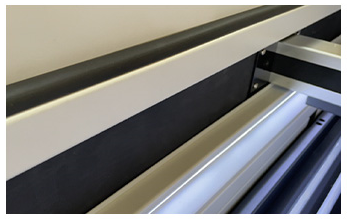

Whole optic path and guide rail clean pack design.

Aeon Laser’s signature clean pack technology has taken the next step in the evolutionary process. Not only are the linear rails and bearing blocks enclosed (as in previous models), but protective curtains on the left and right side of the working area now prevent unwanted particles from the motion system as well as optic path. These will greatly reduce the maintenance of the machine and enhanced the engraving outcome.

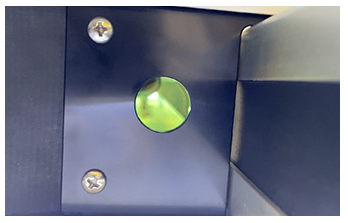

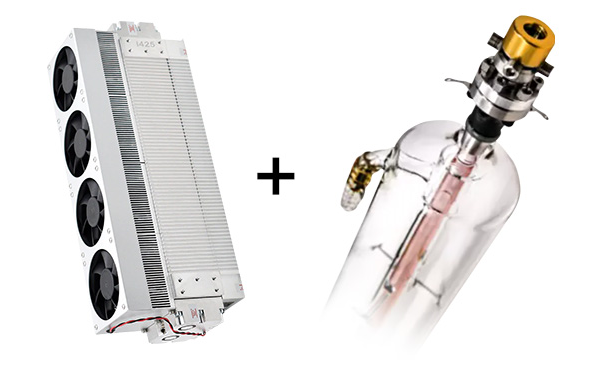

Metal RF & High Power DC glass tube together

Suits for Reci W2/W4/W6/W8 Premium CO2 Glass Tube, 30W/60W RF Metal Tube

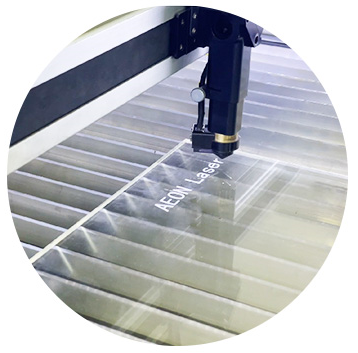

2000mm/sec Scan speed, 5G Acceleration Speed.

Aeon laser’s newly designed lightweight laser head, paired with high-speed, hybrid stepper motors in Super Nova10. 5G acceleration, up to 2000 mm/sec.

Seamless Source Switching

Switching between the RF metal tube and the DC glass tube, happened smoothly and fast. The software automatically triggers the appropriate laser tube and mirror position in roughly half a second.

All in One Design

Super Nova14 is different from Nova14, with built-in 5200 chillers, blower, and air assist.

Integrated Autofocus

The newly designed laser head features an integrated autofocusing mechanism that is lightweight and a whole lot more accurate. Say goodbye to collisions and gouged material.

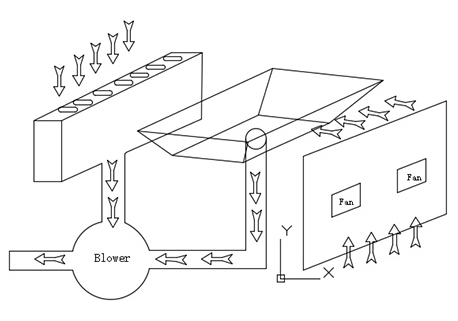

Active Airflow

Say goodbye to excessive soot buildup on your material and in your laser cabinet.

Effective Table and Front Pass Through Door

The Supper Nova14 comes with a slate table together with the honeycomb, which is suitable for cutting and engraving. There is a pass-through door that could pass through extra-length materials.

Powerful and Steady up/down system

The up and down system adopted one belt driving, with a powerful stepper motor, which ensured the table up and down steadily, never tilted. Lifting capacity is up to 120KG.

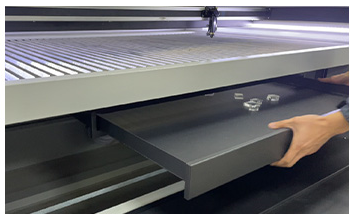

Convenient Scrap and Product Collecting System

All of your cut pieces now fall into a conveniently located compartment below, which can be easily emptied to prevent scrap pieces from piling up and becoming a fire hazard.

Material Applications

| Laser Cutting | Laser Engraving |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

*Cannot cut hardwoods like mahogany

*CO2 lasers only mark bare metals when anodized or treated.

Applications

Product detail pictures:

Related Product Guide:

3ders.org | Co2 Type Laser Cutting Machine

Global Laser Cutters Market Outlook 2019- Trumpf, Han’S Laser, Bystronic, Mazak, Amada, Coherent, Prima Power, Mitsubishi Electric | 1390 Laser Wood Engraving Machine

We are experienced manufacturer. Wining the majority from the crucial certifications of its market for Factory Outlets Laser Engraving Machine Co2 - Nova14 Super – AEON, The product will supply to all over the world, such as: Serbia, Slovenia, Slovak Republic, Our products have won an excellent reputation at each of the related nations. Because the establishment of our firm. we have insisted on our production procedure innovation together with the most recent modern day managing method, attracting a sizable quantity of talents within this industry. We regard the solution good quality as our most vital essence character.

It can be said that this is a best producer we encountered in China in this industry, we feel lucky to work with so excellent manufacturer.